Economic concerns resulting from the ongoing rollercoaster ride with tariff policies

and other factors are casting shades of uncertainty similar to the COVID-19 pandemic

era, supply chain experts said during Fusion 2025.

The Fusion symposium is an annual event hosted by the Auburn University Center for Supply Chain Innovation, and the 2025 version included nearly 200 industry leaders, students and faculty

from around the nation connected to supply chain management.

CSCI Executive Director Brian Gibson welcomed guests with an update on the progress

of the program’s growth at Auburn.

“598 is the number of supply chain management students we have right now. That’s the

most we’ve ever had, so the program is vibrant and doing well,” Gibson said, “and

providing more graduates for you to hire.

“204...is the number of summer interns we have.

“$65.6K... is the average starting salary for our May graduates this year.”

|

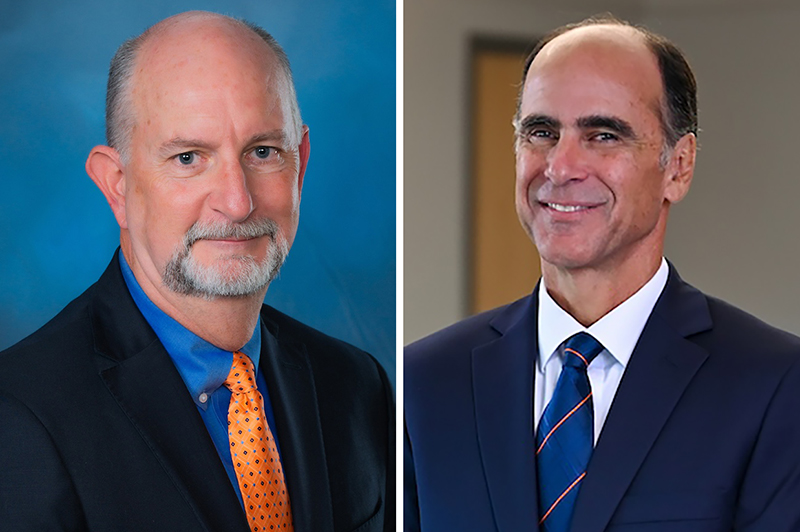

CSCI leadership and supply chain management faculty Brian Gibson (left) and Joe Hanna.

|

“So, the program is doing well,” said Gibson, who announced that he’ll be retiring

in June and that CSCI Co-Executive Director Joe Hanna will assume full control in July. The search for a managing director who will work

with Hanna is nearing completion.

The usual suspects, and then some

Alumna Regenia Sanders, a managing partner with Ernst & Young and a 1999 Auburn graduate, served as the

morning keynote speaker, with Gibson posing several questions to her.

“One of the most widely used words right now is uncertainty,” he said. “What do you

see as the biggest risks?”

“It’s really the usual suspects,” she replied, such as geopolitical risks, inflation

risks, “and we’ve got risks when it comes to regulatory changes. We also have uncertainty

when it comes to risks with the workforce, and that’s something a lot of people don’t

want to talk about, because a lot of our workforce issues really started right after

the pandemic.”

More so since then, Sanders said, “we also have technological disruptions.”

“We’re far more global in our economy now than when we were, say 20 or 30 years ago,”

she said. “There is something to be said about the amount of risk that has been introduced

into the supply chain. But, it’s still the reality of where we stand today with those

uncertainties.”

|

Regenia Sanders, Ernst & Young managing partner, gave the morning keynote address.

|

The impact of tariffs and fast-developing technology on world trade and supply chains

are factors different from the pandemic disruptions, she said.

“It causes us to take a close look at our supply base, and where our suppliers are

so we can better manage the supply risk,” Sanders said, adding that it also is important

to study supply relationships.

“We also have more disruptions in our operations with the introduction of more technology”

leading to more cyber risks, she said. “We have a lot of people out there now who

want to attack our operational technology. A couple of my clients have faced challenges

where their manufacturing line had been literally shut down because of that.

“We really have to pay a lot more attention to how we combat these things.”

However, new technology also can help supply chain managers, Sanders said, such as

practical use of artificial intelligence, or AI.

“There’s a lot of things we can do around personal productivity and leveraging AI,”

she said, citing performance reviews as an example. “There are small productivity

things we can do in our own office. We can also take a look at how we might leverage

some of this new technology when we look at what the demand patterns might be.

“We can also start evaluating our supply base and taking a look at where we might

have risks... and also look for where demand patterns might be.”

Eliminating disruptions in the workforce will remain an important challenge, she said.

A rocky road ahead

Jim Meil, a frequently published economist who works as a principal and industry analysis

for ACT Research, served as the afternoon keynote speaker.

|

Jim Meil, principal at ACT Research and leading industrial sector economist and planner, addressed several economic issues

at the symposium.

|

He addressed several areas of concern that supply chain managers and industry leaders

in the room already recognize as looming threats in the face of massive trade disruption

because of tariffs.

“Remember way back to the summer of 2024, when we thought, boy, when we get this election

out of the way, we can really be focused?” he joked, referring to an earlier period

of wait-and-see regarding the impact of national elections and likely policy changes.

He acknowledged a strong economy that Americans have enjoyed in recent years. “The

problem is, the other shoe is about to drop.”

“We have a service-based economy, by and large,” Meil said. “The problem with that

is, a service economy doesn’t really produce much in freight.”

Tariffs are “definitely on the bad side of the ledger” when it comes to transportation

logistics and supply chain, he said. “It’s going to be tough going for freight movement

in 2025. Maybe it will get better in 2026... but that remains to be seen,” as he sees

President Trump’s policies and tariff announcements going back-and-forth and, at least

for now, continuing to fuel inconsistency.

Regarding manufacturing, “You’re going to hear a lot of the F-word over the next few

months. That is: flat,” Meil said.

Inflation could continue to play a factor, he said, and the stock market is “up and

down, up and down... Watch equity markets, because they tell a story, and I hope the

Trump administration is paying attention to that story.”

Trump’s policies might help ease regulatory concerns, Meil noted, but his tariffs

are affecting trade with our closest partners. “This is a game-changer, that we are

in essence changing our relationship with the rest of the world.”

He pointed to several forecasts that indicate the U.S. is headed toward a recession.

“It’s going to be a tough year ahead,” Meil said. “I’m not anti-Trump, but reality

is reality, and it’s going to be a tough year ahead.”

Auburn alumni share their expertise

Fusion 2025 also featured several panels and “Tiger Talk” discussions, and they included

Auburn alumni among the industry leaders sharing their insight.

For example, Eileen Coparropa, director of enterprise integration at Starbucks, shared an inspiring recap of her

days as an Auburn swimmer on three consecutive national championship teams – 2002,

2003 and 2004 -- and as a flag-bearer for her native Panama in the Olympics. She related

several attributes from what it took to be a champion swimmer to what is required

to be a successful business leader.

Other alumni speakers included

- Tate Curtin (supply chain management ’21), business operations analyst at EDRAY.

- Ahmed Ebrahim (finance ’24), senior vice president of integrations and partner alliances at McLeod

Software.

- Kellie Fisher (supply chain management ’15), director of business development at DHL Supply Chain.

- MK Greenberg (supply chain management ’17), senior value engineer at Celonis.

- Sam Hughes (supply chain management ’17), senior consultant with 09 Solutions.

- Brent Hutto (transportation ’91), chief relationship officer, Truck Parking Club.

- Jim Lager (finance ’90), executive vice president of sales and rental for Penske Truck Leasing.

- Adiola Oladapo (MBA ’05), supply chain management director for Cummins Power Systems.

- Chad Tuck (logistics ’02), market leader with KBC Advisors.

- Denson White (transportation ’99, MBA ’00), chief commercial officer of APM Terminals-Los Angeles.

- Bill Good (management ’93), vice president of supply chain at GE Appliances.

- Matthew Russell, (business analytics, business administration ’21), director of retail at the Auburn

RFID Lab.

- Tyler Hearin (logistics ’07), co-founder of 121 Disposal Co.

Recognizing Fusion 2025 sponsors

Fusion 2025 took place May 1 at the Grand National Marriott in Opelika. Sponsors included:

- Penske

- Buddy Moore Trucking

- Motion Industries

- NTT Data

- TA Services

- SPS Commerce

- APM Terminals

###

CSCI is a highly regarded hub of collaboration between supply chain faculty, students

and industry partners in the Harbert College of Business at Auburn University.

Learn more about the Center for Supply Chain Innovation at Auburn University.

Degrees & Programs

Degrees & Programs

Faculty & Staff

Faculty & Staff

Career Development

Career Development

Recruiters & Industry

Recruiters & Industry